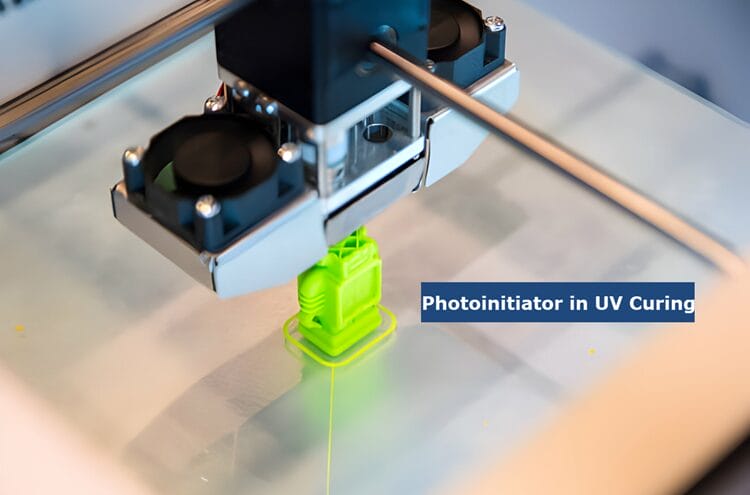

Discover the fascinating world of UV curing and the important role of photoinitiators in this revolutionary process.

In this world, materials can be transformed from liquid to solid with just a flash of light, making it possible to create amazing products with incredible precision.

Photoinitiators, acting as superheroes, harness the power of UV light to initiate polymerization, turning liquid-like substances into solid materials.

These photoinitiators are like the catalysts that make UV curing possible, revolutionizing various industries such as printing, coatings, adhesives, and more.

They play a crucial role in the process of photopolymerization, enabling the transformation of liquid resins into solid objects.

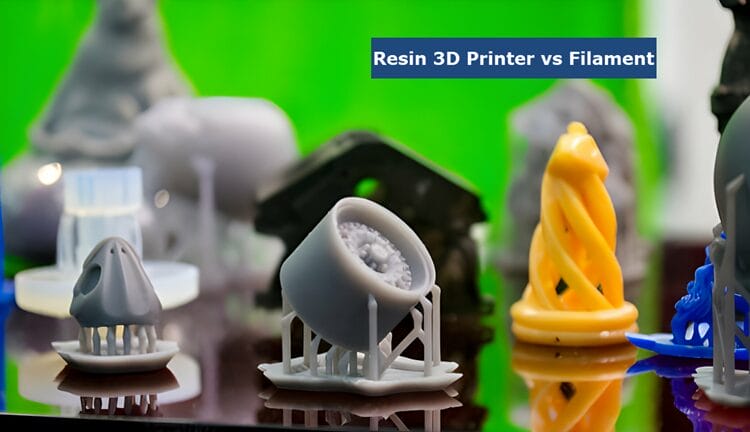

One of the industries benefiting greatly from UV curing is the field of 3D printing. Specifically, the best resin 3D printer utilizes UV curing to create high-quality, detailed prints.

In this process, the photoinitiators within the resin are activated by the UV light emitted by the printer, causing the resin to solidify layer by layer, ultimately forming the desired 3D object.

By understanding the science behind photopolymerization and the secrets of these light-activated initiators, we can fully appreciate the transformative power of photoinitiators in UV curing.

When exploring 3D printing technologies, the choice between Resin 3D Printer vs Filament can significantly impact the outcome of your projects.

What Is UV Curing and How Does It Work?

UV curing is a process that uses ultraviolet light to cure or harden a special type of resin in a short amount of time. The resin contains certain chemicals that react when exposed to UV light, forming a solid material called polymer.

This reaction, known as photopolymerization, transforms the liquid resin into a solid state.

UV light has a specific range of wavelengths, typically between 100 to 400 nm, and the energy from this light triggers the chemical reaction in the resin.

UV curing is used in various applications such as drying inks, adhesion of parts, and coating materials.

It is a versatile technology that offers quick and efficient curing solutions for different industries.

Related: Resin Print Failure Types

Advantages of UV Curing in Coatings and Printing

1. Improved Physical Properties: UV curing systems enhance gloss, abrasion resistance, chemical resistance, strength, elasticity, hardness, and adhesion, resulting in a higher quality and more durable finish.

2. Increased Production Capacity and Speed: UV curing allows for higher throughput, increased machine utilization, and faster production speeds, leading to improved overall production capacity and efficiency.

3. Reduced Work-in-Process: UV curing systems help to reduce manufacturing cycle time, saving capital and improving cash flow by minimizing the amount of work-in-process required.

4. Decreased Clean-Up and Set-Up Labor: UV chemistries only cure when exposed to UV energy, eliminating the need for immediate clean-up and reducing labor time for set-up, especially beneficial in the graphic arts printing industry and other applications.

It is also environmentally friendly, with no VOC emissions, and enables instantaneous drying with UV light exposure, leading to faster shipping and delivery times.

Types and Properties of Photoinitiators for UV Curing

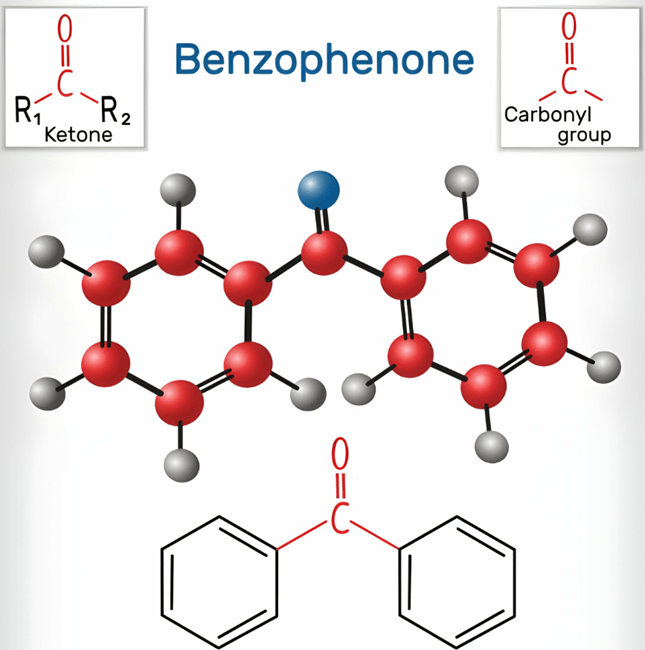

* Benzophenone: This is a commonly used photoinitiator for UV curing. It absorbs UV light energy and transfers it to a reactive species, initiating the curing process. It has a high reactivity and is effective in both thin and thick coatings. However, it requires a long exposure time to achieve complete curing.

* Acetophenone: Another widely used photoinitiator, acetophenone also absorbs UV light and initiates the curing process by transferring the absorbed energy to a reactive species. It has moderate reactivity and is suitable for both low and high-energy curing systems. Acetophenone offers a good balance between reactivity and curing speed.

* Thioxanthone: Thioxanthone is a photoinitiator that has a high reactivity and is effective in UV curing systems. It absorbs UV light and transfers the energy to a reactive species, initiating the curing process. Thioxanthone is particularly useful for curing systems that require a fast curing speed and is often used in combination with other photoinitiators to enhance the curing process.

* Other Types: Apart from benzophenone, acetophenone, and thioxanthone, there are many other types of photoinitiators available for UV curing. These include benzoin, benzoin methyl ether, camphor quinone, and many more. Each type has its specific properties and reactivity, allowing for customization of the curing process based on specific application requirements.

Exploring Type I and Type II Photoinitiators

Photoinitiators are substances that react to UV light by generating reactive species that initiate the polymerization process.

There are two main types of photoinitiators: Type I and Type II.

Type I photoinitiators undergo a cleavage reaction when exposed to UV light, resulting in the formation of two highly reactive radical species that initiate polymerization. These photoinitiators become incorporated into the polymer matrix.

On the other hand, Type II photoinitiators require a hydrogen donor, usually an amine, to react with under UV light. This reaction forms two radicals that can initiate polymerization.

Unlike Type I photoinitiators, Type II photoinitiators are not incorporated into the polymer, but the hydrogen donor is.

Chemical Reactions and Free Radical Generation

Chemical reactions and free radical generation are essential processes in UV curing. Free radical-generating photoinitiators, such as Type I and Type II, initiate the polymerization reaction when exposed to UV light.

Type I photoinitiators undergo homolytic cleavage to produce free radicals, while Type II photoinitiators require a co-initiator to abstract hydrogen and split a bonding pair of electrons.

This polymerization reaction transforms liquid-like substances into solid materials, enabling the curing or hardening of resins.

UV curing, utilizing high-intensity UV light, triggers a chemical reaction that crosslinks and solidifies materials, making it widely used in various industrial applications.

Role of Cationic Photoinitiators

Cationic photoinitiators play a crucial role in polymerization reactions, particularly in epoxy curing. These chemical compounds generate acids upon exposure to UV radiation, initiating the polymerization process.

Iodonium-type cationic initiators, with their long-chain alkyl substituents, are highly compatible with resins and have low toxicity.

Additionally, the addition of a sensitizer can enhance their sensitivity and allow for the use of longer wavelengths.

Overall, cationic photoinitiators are essential for achieving efficient and controlled polymerization reactions in various applications.

Factors Affecting Photoinitiator Absorption of UV Light

The absorption of UV light by photoinitiators can be influenced by factors such as the chemical composition of the photoinitiator, the concentration of the photoinitiator in the adhesive, and the wavelength and intensity of the UV light source.

These factors can affect the efficiency of the photoinitiator in initiating the curing process of the adhesive.

Oxygen Inhibition and Its Impact on UV Curing

Oxygen inhibition is a phenomenon that occurs during the UV curing process where the presence of oxygen prevents the complete curing of the adhesive or coating.

This can result in a sticky surface even after curing, which is problematic for applications like PCB coatings.

UV Curing Applications and Processes

UV curing is a photochemical process that uses high-intensity ultraviolet light to instantly cure or dry inks, coatings, or adhesives in various industries such as printing, plastic packaging, and metal decorating.

The process offers benefits like increased durability, high-quality finish, flexibility, and instant curing.

UV formulations, consisting of liquid monomers and oligomers mixed with photoinitiators, are exposed to UV energy, resulting in the immediate hardening or curing of the materials.

This allows for faster production, energy savings, precise UV radiation adjustment, and continuous processing.

UV Curing in 3D Printing and Screen Printing

UV curing is a process used in 3D printing and screen printing that involves curing or hardening a material using ultraviolet light.

It offers several advantages such as being environmentally friendly with no volatile organic compounds emitted during curing, and the ink does not dry on the screen, unlike solvent-based inks.

Impact of UV Radiation and Visible Light on Curing Depth

The impact of UV radiation and visible light on curing depth is determined by their respective wavelengths.

UV light with wavelengths at 385 nm or higher provides more uniform curing and can penetrate and cure adhesives in thicker sections.

As the wavelength gets closer to the visible range, it becomes easier to cure through larger gaps.

Role of UV LED Lights in Photopolymerization

UV LED lights play a crucial role in the process of photopolymerization. When UV light of specific wavelengths and intensity is applied to the monomers, it triggers a reaction that causes them to crosslink and form a solid polymer network.

UV LED curing lamps offer various advantages, including environmental benefits such as no ozone emissions or hazardous substances, economic benefits like low energy consumption and long durability, and application advantages like low heat generation and instant switching on and off.

UV LED technology also provides uniform and consistent light intensity, resulting in more predictable and repeatable finished results.

Future developments in UV LED technology aim to enhance productivity, optimize cure performance, and widen the plate-making window.

Advancements in UV Curing for Manufacturing and Coating Industries

Advancements in UV curing for manufacturing and coating industries have led to improved control over parameters like UV intensity and exposure time.

This allows for precise and consistent curing, resulting in high-quality outcomes across different applications.

Conclusion

In conclusion, photoinitiators play a crucial role in the revolutionary process of UV curing. They harness the power of UV light to initiate polymerization, transforming liquid-like substances into solid materials.

UV curing offers numerous advantages in industries such as printing, coatings, and adhesives, including improved physical properties, increased production capacity and speed, reduced work-in-process, and decreased clean-up labor.

Different types of photoinitiators, such as benzophenone, acetophenone, and thioxanthone, have specific properties and reactivity, allowing for customization of the curing process based on application requirements.

Additionally, the distinction between Type I and Type II photoinitiators and the role of cationic photoinitiators in epoxy curing further contribute to the versatility and efficiency of UV curing.

With advancements in UV LED technology and ongoing developments in the field, the future of UV curing looks promising, offering even greater control and optimization for manufacturing and coating industries.

The transformative power of photoinitiators in UV curing continues to revolutionize various sectors, making it an exciting field to explore.