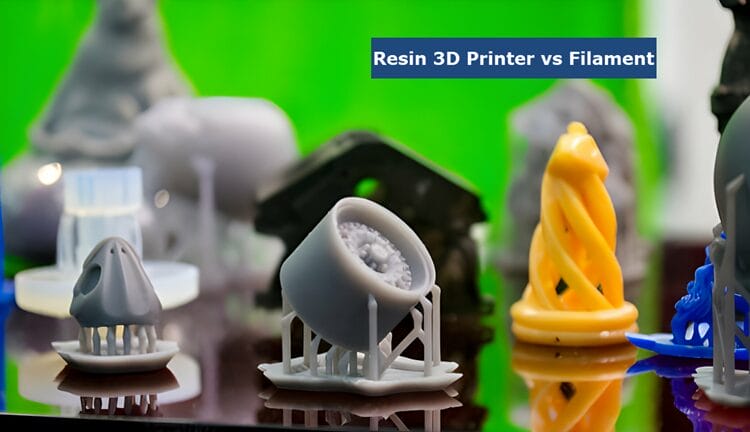

Are you torn between choosing the best resin 3D printer vs filament for your next 3D printing venture?

Delve into the world of 3D printing technologies with us as we unravel the distinct offerings of Resin and Filament printers. Uncover the key differences, benefits, and trade-offs of each option to guide you toward making an informed decision.

Whether you're aiming for precision or ease of use, this comparison will shed light on which path to take in the Resin 3D Printer vs Filament dilemma.

In the realm of resin printing, understanding the photoinitiator in UV curing is crucial for achieving optimal results. This component plays a significant role in the curing process, influencing the quality and properties of the final resin prints.

Furthermore, when exploring resin printing, being aware of resin print failure types is essential for troubleshooting and improving your printing success rate. Recognizing common failure types such as layer adhesion issues or curing inconsistencies can help you refine your settings and printing techniques for better outcomes.

What Is the Difference between Resin and Filament 3D Printing?

Resin 3D printing offers higher quality, detailed prints with smoother finishes but takes longer, while filament printing is faster and produces prints with higher tensile strength. The choice between the two depends on the project's requirements and desired outcome.

Understanding the Properties of Resin Printing

1. Temperature:

The ideal temperature range for resin printing is 75°F-86°F or 24°C-30°C, as it affects the curing process and final print quality.

2. Deformation:

Resins can be categorized based on their deformation behavior at the break, with tough resins having low deformation and high-impact resistance, while ABS or high-impact resins offer moderate deformation and good toughness.

3. Curing Time:

This refers to the time it takes for the resin to solidify after exposure to light, typically ranging from 1.5-3 seconds per layer.

4. Flexibility:

Resins can range from flexible/elastic like rubber to rigid, with each type offering specific properties for different applications.

5. Tensile Strength:

Tough resins have high tensile strength (55.7 MPa) and modulus of elasticity (2.7 GPa), making them suitable for sturdy, shatter-resistant parts.

6. Viscosity:

Photopolymer resins have low viscosity, allowing for easy flow during printing and influencing bonding between layers.

7. Color Influence:

The color of resin affects properties, with grey-suited for fine details, white for smooth surfaces, and standard resin ideal for concept modeling and rapid prototyping.

8. Types of Resins:

Resins for engineering, dental, and jewelry applications offer specific properties like high strength, flexibility, and biocompatibility, each tailored for different uses and industries.

9. New Resin Innovations:

Recent resin developments focus on enhancing properties for specific applications, leading to a wider range of materials with diverse characteristics.

10. Manufacturers' Variability:

Different manufacturers may have variations in resin properties and names, making it important to consult specifications for accurate material selection.

Exploring the Characteristics of Filament Printing

1. PLA Filament:

* Description: PLA is a beginner-friendly standard filament known for its ease of use, low cost, and availability in various colors.

* Properties: Medium durability, rigid stiffness, print temperature of 180-230°C, and print bed temperature of room temp to 60°C.

2. ABS Filament:

* Description: ABS is stronger than PLA but requires more effort to print due to warping issues when cooling.

* Properties: Medium to high durability, rigid stiffness, print temperature of 220-260°C, and print bed temperature up to 110°C.

3. PETG, PET, & PETT Filament:

* Description: Commonly used filaments with high strength, impact resistance, and clear/translucent appearance.

* Properties: High durability, rigid with slight flexibility, print temperature of 220-250°C, and print bed temperature of 60-90°C.

4. TPE, TPU, TPC (Flexible) Filaments:

* Description: Flexible filaments suitable for strong but flexible prints, commonly used for durable objects.

* Properties: High durability, semi-flexible to flexible stiffness, print temperature of 220-240°C, and print bed temperature of 40-70°C.

5. Nylon Filament (PA):

* Description: Nylon is known for its strength and durability, requiring specific printing conditions to prevent warping.

* Properties: High durability, rigid in thick layers but flexible in thin layers, print temperature of 230-300°C, and print bed temperature up to 110°C.

6. Polycarbonate Filament (PC):

* Description: Polycarbonate offers high-temperature resistance, strength, and transparency, suitable for industrial-grade prints.

* Properties: High durability, semi-flexible to rigid stiffness, print temperature of 270-350°C, and print bed temperature of 135-150°C.

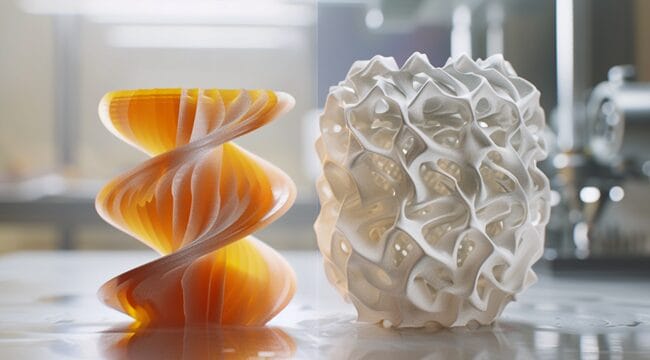

Comparing Printing Processes and Outcomes

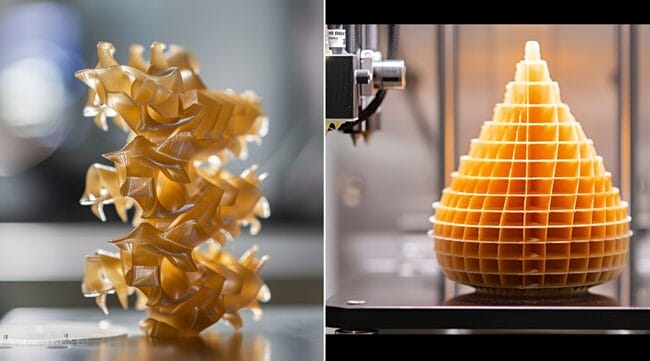

Resin 3D printers use liquid resin cured by light to create highly detailed and smooth finished prints, suitable for small, delicate parts. Filament 3D printers melt and extrude filament to produce faster prints with higher tensile strength, ideal for larger and stronger parts.

Resin printing is more expensive but offers superior quality, while filament printing is more cost-effective and versatile for less detailed projects.

Application Differences between Resin and Filament Printing

Resin 3D printing is commonly used for applications requiring high detail, accuracy, and superior mechanical properties like prototyping, engineering, dentistry, and jewelry making. On the other hand, filament printing is versatile for producing functional parts, prototypes, molds, medical devices, and toys.

Resin printing excels in intricate designs and fine details, while filament printing is more practical for a wide range of industrial and educational applications.

Cost Differences between Resin and Filament Printing

Filament 3D printing is generally more cost-effective than resin 3D printing due to the lower upfront cost of purchasing filament compared to resin.

While resin printing may offer higher quality prints and faster printing times, the ongoing costs of resin and maintenance can add up, making filament printing a more budget-friendly option for many users.

Which 3D Printing Technology Is Better, Resin or Filament?

When choosing between resin and filament 3D printing technologies, consider filament FDM printing for durable and budget-friendly prints. Resin printing is better suited for high-quality and intricate prints, albeit at a higher cost.

Ultimately, the choice depends on whether you prioritize durability and cost-efficiency or superior quality and detail.

Comparing Print Speed and Quality of Resin vs Filament Printers

Resin printers are slower than filament printers but offer higher-quality prints with smoother finishes. Filament printers are better for producing larger, stronger parts, while resin printers excel in fine details and precision on smaller parts.

Resin printers typically take longer to print, with some models taking up to 8 hours per print, while filament printers can be faster for larger prints.

Understanding the Printing Material and Its Impact on the Choice

The choice between resin and filament 3D printing depends on the specific use case. Filaments used in FDM printing are generally more durable than regular resins, with materials like ABS, PLA, PETG, nylon, and polycarbonate offering higher tensile strengths and impact resistance.

However, tough resin stands out as stronger than some filament options.

Filament printing provides a broader material selection, larger build volumes, and lower costs, making it a versatile choice for various applications.

Advantages and Limitations of Resin 3D Printers

Resin 3D printers offer high-quality results with intricate details and textures, making them ideal for visual prototypes and art models. However, resin parts can be weak and brittle, limiting their use for end-use applications.

Additionally, resin printing can be more costly, requires technical equipment, and involves post-processing steps like cleaning excess resin and exposure to fumes.

Advantages and Limitations of Filament 3D Printers

Filament 3D printers offer a range of advantages such as affordability, high strength, and the ability to produce functional prototypes. However, they typically have lower resolution and quality compared to resin printers.

Filament types like ABS, PETG, and PLA each have specific strengths and limitations, ranging from high durability and thermal stability to issues like warping and lower flexibility.

Additionally, FDM printing, while cost-effective, is limited in terms of speed, surface finishes, and color options.

What Are the Main Considerations When Choosing between Resin and Filament 3D Printers?

When choosing between resin and filament 3D printers, important considerations include object size, resolution, material options, maintenance requirements, surface finish, strength, and material cost.

Resin printers are better for smaller, more precise parts with smoother surfaces but are more expensive and require more maintenance, while filament printers are more versatile, affordable, and suitable for larger, sturdier parts.

How Do Resin and Filament 3D Printers Work?

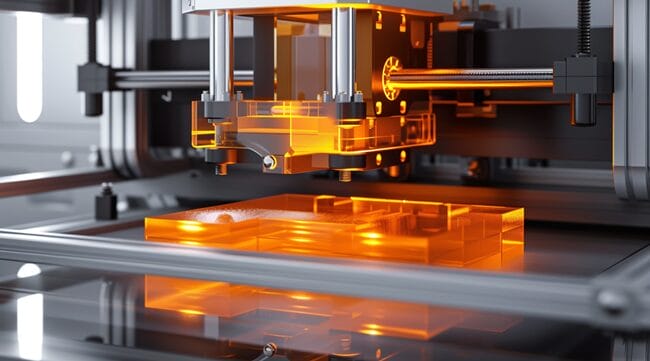

Resin 3D printers use UV light to solidify liquid photopolymer resin layer by layer, creating objects by curing the resin with precise laser exposure. Filament 3D printers melt plastic filament, which is then extruded through a nozzle to build objects layer by layer.

Comparing the Process of Solidifying the Resin and Melting the Filament

The process of solidifying resin in 3D printing involves curing a liquid photopolymer with UV light to create objects with high detail and smooth surfaces.

In contrast, melting filament in 3D printing uses a heated extruder to melt thermoplastic material, depositing it layer by layer to build objects with potentially rougher surface finishes.

Resin printing is known for its intricate details and smooth surfaces, while filament printing is popular for its availability and adaptability.

Understanding the Role of UV Light in Resin Printing

UV light is crucial in resin printing as it triggers photopolymerization, transforming liquid resin into a solid form when exposed to a computer-controlled UV laser.

This process enables layer-by-layer construction of 3D prints as the resin hardens under UV light, determining the polymerization and curing based on exposure time and material properties.

What Are the Common Misconceptions About Resin and Filament 3D Printing?

Let us examine the common misconceptions about resin and filament 3D printing:

Dispelling Myths About the Cost of Resin 3D Printers Compared to Filament Printers

Resin 3D printers are often perceived as more expensive than filament printers, but the true cost analysis reveals that resin printing entails higher initial purchase and ongoing maintenance costs.

While the gap in printer prices is narrowing, resin materials are pricier than filament, resulting in significantly higher costs per print.

Additional equipment and maintenance requirements further contribute to the overall expense of resin 3D printing.

Misconceptions About the Safety and Handling of Resin vs Filament Printing

1. Resin prints are not inherently brittle; advancements in resin technology have made it possible to create strong and tough prints suitable for a wide range of applications, including dental and medical uses.

2. New generation resins emit minimal noxious fumes, offering a more pleasant printing experience without compromising on precision, curing times, shrinkage rate, detail, or finish quality.

3. While resin printing can be messy due to spillages and staining, spills can be easily cleaned with water, eliminating the need for isopropyl alcohol during post-processing and making cleanup more convenient.

4. Resin printing is no longer limited to rigid prints; modern resins allow for the creation of bendable and compressible parts, expanding the range of applications beyond just miniatures and prototypes.

5. High-quality resins do not necessarily come with a high price tag; affordable options are available without compromising on quality, making resin printing accessible to a wider audience.

6. Basic safety measures are crucial when handling resin for 3D printing due to the unknown composition of raw materials used in resin manufacturing. Protect yourself by wearing gloves, ensuring proper ventilation, and storing materials securely away from pets and children to prevent potential health issues.

Clarifying the Environmental Impact of Resin and Filament Printing Processes

The environmental impact of resin and filament 3D printing processes is significant. PLA filament, often touted as eco-friendly, faces challenges with proper composting and disposal, potentially ending up in landfills and oceans.

The resin used in SLA printing is toxic and harmful to marine ecosystems when disposed of improperly.

Both processes contribute to environmental issues such as raw material extraction, energy consumption, emissions, waste generation, and end-of-life disposal challenges, highlighting the need for more sustainable practices in the 3D printing industry.

Examining the Durability of Objects Printed with Resin or Filament Technology

When examining the durability of objects printed with resin or filament technology, filament 3D printers using materials like ABS, PLA, PETG, nylon, and polycarbonate generally produce more durable prints compared to resin printers.

Filament prints are known for their higher tensile strength and impact resistance, making them suitable for functional parts.

However, resin printing is preferred for intricate and detailed models despite the lower durability of traditional resins, with tough resin being an exception known for its strength surpassing some filament materials.

Conclusion

In conclusion, the debate between Resin 3D Printers and Filament Printers continues to captivate the 3D printing community, each technology offering unique benefits and trade-offs.

While Resin printing excels in delivering high-quality, intricate prints with smooth finishes, Filament printing stands out for its speed and strength, making it ideal for larger, functional parts.

Ultimately, the choice between Resin and Filament printers boils down to your specific project requirements and priorities.

As the layers of innovation unfold in the 3D printing world, the Resin vs Filament dilemma remains a delightful conundrum.

Choosing between the meticulous precision of Resin and the robust versatility of Filament is akin to selecting between a master artist and a seasoned engineer – both indispensable in their own right.

So, whether you lean towards the finesse of Resin or the resilience of Filament, remember that in the realm of 3D printing, the creation is limited only by your imagination.

Embrace the technology that best suits your vision and watch your designs come to life in ways previously unimaginable.